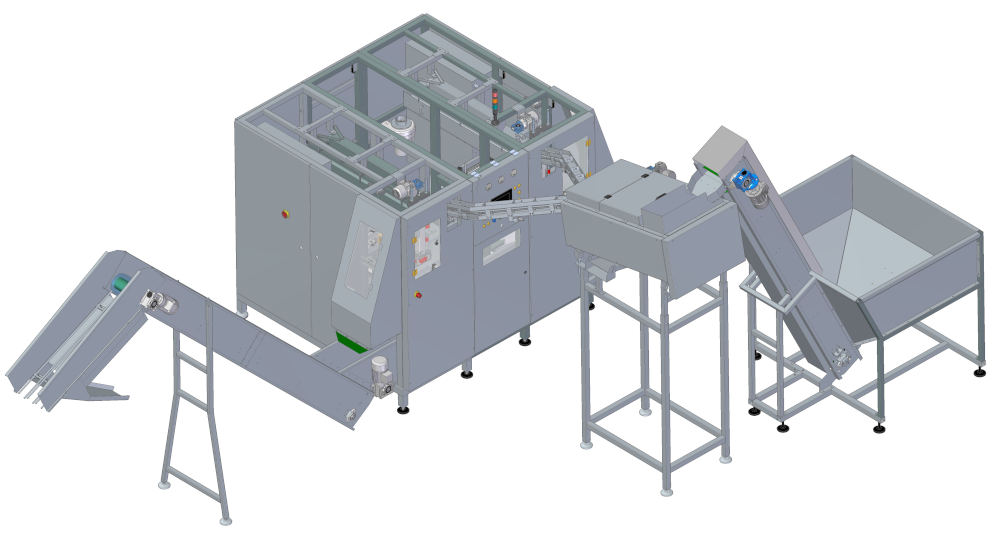

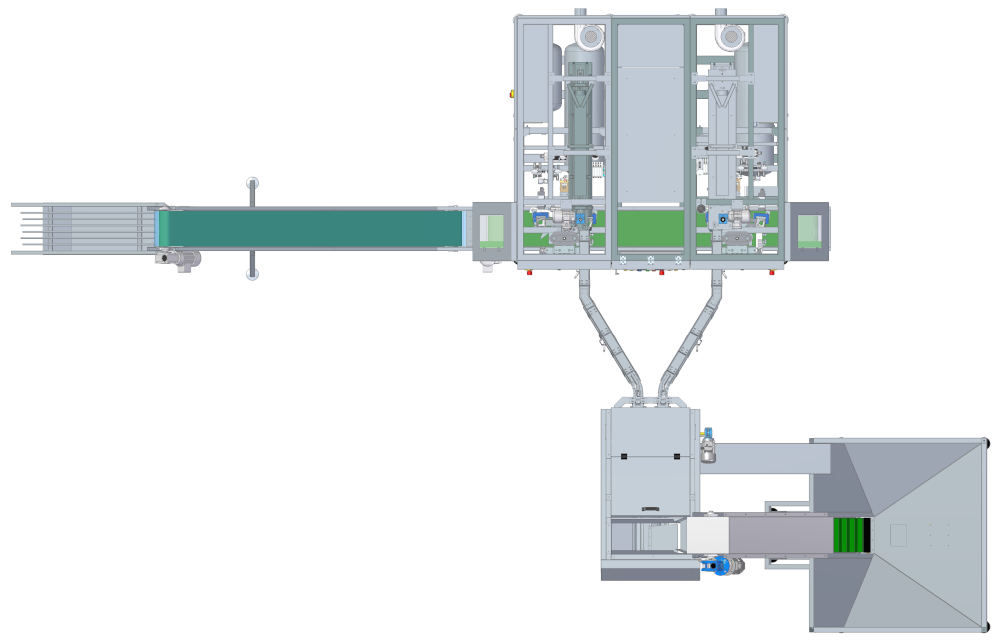

Blowing machine e-Blow 4

General characteristics

- Automatic machine for PET package production in the 0.25-3.0 Ltr. range.

- Low energy consumption

- Quick and simple mould exchange system

- Possibility to increase capacity through modular line extensions

- Adaptation to any working conditions

- Automatic preform feeding system.

- System for independent adjustment of each row of lamps to optimize the plasticization of the preforms.

- Software that monitors the condition of the machine and related equipment in order to optimize the production.

- Touch screen control system for easy operation by the operator offering functions:

– Creation and modification of various operational programmes,

– Display of technical data of the blowing machine together with production information,

– Oven power setting, capacity and all other parameters that can be adjusted.

– Display of diagnostic messages. - Compressed air recovery system ,,AIR Recuperation’’ – OPTION .

| Blowing pressure | Low pressure - 10 bar High pressure - 25 bar |

| Bottle volume | 0,25 ÷ 3 L |

| Max. bottle Height | 380 mm |

| Max. Bottle neck Diameter | 42 mm |

| Max. Bottle Diameter | 115 mm |

| Capacity* | 500 ml - 4 200 bottles/h 1000 ml - 4 000 bottles/h 1500 ml - 3 800 bottles/h 3000 ml - 2 500 bottles/h |

| Plasticizing units (modules) | 2 pcs |

| TOTAL INSTALLed POWER | 60 kW - 400V, (3P + N + PE), 50 ÷ 60 Hz, Cos φ 0,9 |

| Air consumption (10 bar )* bottle 1l | 2,0 m3N/min |

| Air consumption (25 bar)* Bottle 1L | 3,0 m3N/min |

| Number of closing units | 2 pcs |

| Number of mould cavities | 4 (2+2) |

| Control voltage | 24 V DC |

| Efficiency | 96% |

| Blowing machine dimensions, Weight | l. 2070mm w. 2900 mm h. 2 200 mm weight:2 300 kg |

| PREFORM feeeder dimensions, Weight | l. 2 400 mm w. 2 000 mm h. 3 100 mm weight: 560 kg |

*(depending on the size, weight and shape of the preform and bottle)

Air recovery – OPTION

Low air consumption thanks to recuperation system AIR Recuperation realized by optimization of pneumatic processes with the use of special valves from company

- less air necessary for machine operation

- possibility of using a smaller and cheaper compressor,

- extension of compressor service intervals

- lower energy consumption

- quieter machine operation, meeting more stringent standards

Design and manufacture of PET bottle blow moulds

Every project starts with the development of a bottle. The shape and weight of the bottle must fully meet the needs of the customers, but at the same time all the requirements related to PET bottle production technology must be met.

allowing for easy operation

It is a fully automatic machine. Thanks to the use of a microprocessor PLC with a touch screen, it is possible to control the operation of the machine on an ongoing basis, to change settings and parameters. It is also possible to save product recipes.